ZHEJIANG BHS JOURNAL BEARING CO.,LTD. located in FengXian District of ZheJiang, the company's brand "BHS", is a professional tilting pad thrust bearings manufacturers and Tilting pad bearings factory...

High-precision bearings play a crucial role in ensuring the smooth and efficient operation of compressors. These components are essential in industries ranging from refrigeration to air compression and industrial machinery. By providing critical support to rotating parts, bearings minimize friction and wear, ensuring that compressors function efficiently under various conditions.

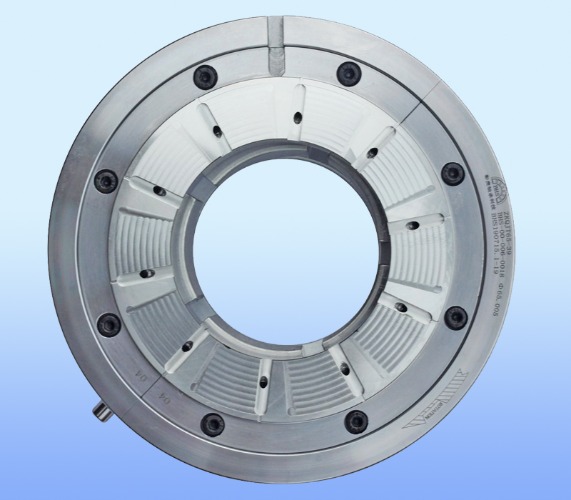

Compressor bearings are specifically designed to withstand high loads and reduce friction in compressors. They are often subjected to conditions such as high pressure, temperature fluctuations, and rapid rotational speeds. These bearings are classified into different types based on the design and application requirements.

These components are integral to maintaining the balance, efficiency, and longevity of compressors.

The precision of compressor bearings directly impacts the overall performance of the compressor. Here are several reasons why high-precision bearings are essential:

Reduced Friction: High-precision bearings are manufactured to minimize internal friction. This reduction in friction results in less heat generation and lower energy consumption, improving compressor efficiency.

Longer Lifespan: By minimizing wear and tear, high-precision bearings extend the operational life of compressors, reducing the need for frequent replacements and maintenance.

Enhanced Stability: Precision bearings maintain accurate alignment of moving parts, which is crucial for maintaining the stability of compressors under high-pressure and high-speed operations.

Noise Reduction: High-precision bearings contribute to quieter compressor operation, which is particularly important in industries where noise levels must be controlled.

Consistent Performance: Precision bearings ensure that compressors operate consistently, without fluctuations in speed or load, contributing to smoother operations.

Different types of bearings are used in compressors, each tailored to specific applications:

| Bearing Type | Function | Key Features |

|---|---|---|

| Radial Bearings | Support axial and radial loads | High load capacity, precision design |

| Thrust Bearings | Handle axial loads and support rotation | High axial load tolerance |

| Angular Contact Bearings | Designed for both axial and radial loads | Handles combined loads |

| Self-aligning Bearings | Prevent misalignment | Ensures smooth and reliable rotation |

Each type of bearing is designed to handle specific loads and conditions, ensuring that compressors function efficiently and reliably.

The materials used in high-precision compressor bearings are critical to their performance. High-grade steel, ceramic materials, and advanced coatings are often used to enhance durability, reduce friction, and improve resistance to wear. Precision manufacturing processes, including CNC machining and heat treatment, ensure the exact tolerances necessary for bearing function.

While compressor bearings are essential for smooth operation, they face several challenges:

Heat Generation: Compressors generate significant heat, which can wear down bearings over time. Precision bearings help to manage this heat, but in conditions, cooling systems may also be required.

Contamination: Bearings can be damaged by particles and contaminants in the compressor environment. Proper sealing and maintenance are essential to prolong bearing life.

Vibration and Shock Loads: High-speed operation and sudden shock loads can cause premature failure of bearings. High-precision bearings are designed to handle such loads but require careful monitoring.

Compressor bearings are found in a variety of industrial applications, each with specific requirements:

Each industry has unique demands on bearing performance, requiring different materials, designs, and specifications.

Routine maintenance is essential for ensuring the longevity of compressor bearings. Some key maintenance practices include:

High-precision bearings are indispensable components in compressors, ensuring reliability, efficiency, and longevity. By understanding the importance of these bearings and the factors that affect their performance, industries can optimize compressor operations and minimize downtime.

1. What is the role of a compressor bearing?

Compressor bearings support the rotating shaft, reducing friction and wear while maintaining stability during operation.

2. How do high-precision bearings improve compressor performance?

They reduce friction, enhance stability, and extend the lifespan of compressors, ensuring smooth and efficient operation.

3. What are the common types of bearings used in compressors?

The common types are radial bearings, thrust bearings, angular contact bearings, and self-aligning bearings.

4. How can I ensure the longevity of compressor bearings?

Regular lubrication, inspection for wear, and temperature control can help prolong bearing life.

5. What materials are commonly used in compressor bearings?

Steel, ceramics, and coated materials are commonly used, each offering specific benefits for performance and durability.