Can contact seals in turbomachinery bearings improve equipment reliability and performance?

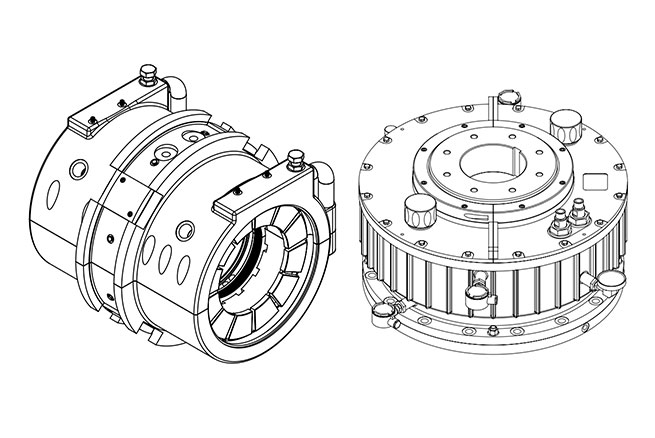

Turbomachinery bearings usually adopt a sealed structure to reduce friction and wear and prevent external dust, impurities, etc. from entering the inside of the bearing, thereby ensuring the normal operation of the turbomachinery. Contact seals contact the shaft and bearing shell through contact seals such as rubber and plastic to form a certain sealing effect.

The main function of the contact seal is to prevent friction and wear problems in turbomachinery bearings caused by external dust, impurities, etc. entering the inside of the bearing. During the operation of turbomachinery, the centrifugal force and inertial force generated by high-speed rotation will also have a certain impact on the bearings. Therefore, the use of contact seals can ensure the normal operation of the bearing and reduce bearing damage and performance degradation caused by external factors.

Contact seals are usually made of elastic materials such as rubber and plastic and have a certain degree of softness and elasticity. When the mechanical equipment is in operation, the contact seal will contact the shaft and bearing housing to form a certain pressure, thereby forming a sealing effect. The material selection of the contact seal is very important. On the one hand, it must consider its compatibility with the shaft and bearing housing. On the other hand, it must have wear resistance, corrosion resistance, anti-aging and other properties to ensure the long-term service life of the seal.

When using contact seals, attention needs to be paid to the contact between the seal and the shaft and bearing housing. If the contact is poor, it may cause excessive friction and heat during the operation of the turbomachinery, and even cause problems such as oil leakage. Therefore, during installation and use, it is necessary to ensure the correct installation position and contact area of the contact seal, and to perform seal inspection and maintenance.

Contact seals play a vital role in turbomachinery bearings. They can reduce friction and wear and prevent external dust, impurities, etc. from entering the inside of the bearing, thereby ensuring the normal operation of turbomachinery. By properly selecting and maintaining contact seals, you can extend the service life of bearings and improve equipment reliability and performance.

Will turbomachinery bearings suffer wear problems during long-term high-speed rotation?

Turbomachinery bearings will face serious wear problems during long-term high-speed rotation. The bearings of turbomachinery are subject to huge loads and friction. The contact between the bearing and the journal will generate friction, which will cause wear on the bearing surface. As wear continues to accumulate, the metal layer on the bearing gradually wears and thins, and the gap between the journal and the bearing will also decrease. The reduced clearance will cause the bearing to not operate properly and may even cause mechanical failure.

There are many reasons for bearing wear. First, when the turbomachinery is running, the load borne by the bearing will cause the local pressure on the bearing surface to increase, thereby causing wear. In addition, bearings will generate higher temperatures during long-term high-speed rotation, which will increase the bearing surface temperature. Thermal expansion will make the contact between the bearing and the journal closer, thereby increasing the contact surface area and further aggravating wear. In addition, during operation, bearings will also be subject to particle contamination from the outside and the intrusion of foreign matter. These particles and foreign matter will accelerate the wear of the bearing.

In order to reduce bearing wear problems, a series of measures need to be taken during the design and manufacturing process of wheel machinery. First of all, the selection of bearings must be reasonable, and bearings suitable for high-speed rotation should be selected, such as ceramic bearings, high-speed bearings, etc. Secondly, the lubrication system of turbomachinery must be improved to ensure that the bearings are fully lubricated. Proper lubrication can reduce bearing friction and reduce bearing wear. At the same time, the quality of the lubricating oil also needs to be guaranteed. The purity of the lubricating oil must be ensured to avoid particle contamination and foreign matter intrusion. In addition, turbomachinery needs to regularly detect and maintain bearings during operation, and promptly replace seriously worn bearings to avoid serious mechanical failures.

The wear problem of

turbomachinery bearings during long-term high-speed rotation is a complex and serious problem. To solve this problem, we need to start from many aspects such as bearing selection, improvement of lubrication system, and regular testing and maintenance of bearings. Only by taking comprehensive measures can we effectively solve the wear problem of turbomachinery bearings and ensure their normal operation.