What measures can be taken to solve the vibration and noise problems caused by sliding bearing parts?

Sliding bearings are a key component widely used in industrial machinery to support and rotate shafts. However, vibration and noise problems caused by sliding bearing parts are often encountered, and these problems will not only reduce the operating efficiency of the machinery, but also cause damage to the health of the operators. To resolve this issue, consider upgrading to higher quality bearings or using self-lubricating bearings to reduce the problem.

Upgrading to higher quality bearings is one of the effective ways to solve vibration and noise problems. Low-quality bearings are prone to friction, resulting in uneven contact between the bearing and shaft, causing vibration and noise. High-quality bearings have better dimensional accuracy and flatter surfaces, which can provide better damping effects and reduce friction and vibration. Therefore, upgrading to higher quality bearings can effectively reduce the occurrence of vibration and noise problems.

Using self-lubricating bearings is also a viable solution to vibration and noise problems. Sliding bearings usually require lubricants to reduce friction, but in some special working environments, the use of lubricants may be difficult. Self-lubricating bearings have built-in solid lubricant, which can automatically release lubricant during long-term operation, thereby reducing friction and vibration. Therefore, using self-lubricating bearings can effectively reduce vibration and noise problems and provide more reliable performance.

Regular maintenance and care of bearings is also an important step in preventing vibration and noise problems. For example, regularly check bearings for wear or damage, and promptly replace or repair problematic bearings. Also, clean and lubricate bearings regularly to keep them running properly. Through regular maintenance and maintenance of bearings, the occurrence rate of failure can be reduced, and the generation of vibration and noise can be reduced.

Vibration and noise problems caused by

sliding bearing parts are often encountered, which can be solved by upgrading to higher quality bearings or using self-lubricating bearings. Additionally, regular maintenance and care of bearings is key to preventing problems. Through these measures, the vibration and noise caused by sliding bearings can be effectively reduced, and the operating efficiency of the machinery and the working environment of the operators can be improved.

Can sliding bearing parts reduce the heat and loss generated by friction?

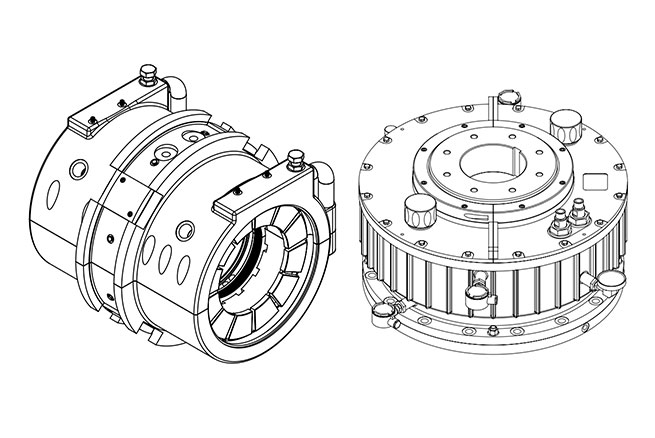

Sliding bearings are commonly used mechanical components whose function is to provide a smooth sliding surface between two mutually contacting surfaces to reduce friction and wear. The design and manufacture of sliding bearings is very important to effectively reduce heat and energy loss due to friction, thereby protecting mechanical components from excessive wear.

When mechanical parts are in motion, the temperature will rise due to the presence of friction, which may cause deformation, damage, or even failure of the entire mechanical system. By using sliding bearings, a lubricating film can be formed between the sliding surfaces, reducing friction and thus reducing the heat generated by friction. Sliding bearings usually use lubricating oil or grease as the lubricating medium to maintain the lubrication state of the bearing surface. The existence of this lubricating film can effectively reduce bearing friction and wear and extend the service life of mechanical components.

In addition to reducing heat and losses, sliding bearings also have an important function: protecting mechanical components from excessive wear. When mechanical parts are in motion, some tiny irregular shapes will be produced due to incomplete compatibility between the contact surfaces, which may lead to increased wear of the parts. Sliding bearings reduce wear problems caused by friction by providing a smooth sliding surface on which mechanical parts can slide. In this way, mechanical components can maintain normal operation for a longer period of time, reduce the frequency of repairs and parts replacement, and improve the reliability and stability of the mechanical system.

Sliding bearings also absorb vibration and impact forces, ensuring the stability of mechanical components. In mechanical systems, vibration and impact forces may cause deflection or oscillation of the motion axis, which may affect the normal operation and accuracy of mechanical components. Through sliding bearings, these vibrations and impact forces can be absorbed and damped by transmitting them to the sliding surface, thereby effectively preventing axial deflection or oscillation and maintaining the stability of mechanical components.

As an important mechanical component, sliding bearings can reduce the heat and loss generated by friction and protect mechanical components from excessive wear. They also absorb vibration and impact forces, ensuring there is no axial deflection or oscillation. Through the careful design and use of high-quality sliding bearings, the performance and life of mechanical systems can be improved, the cost of repair and replacement parts can be reduced, and the reliability and stability of mechanical equipment can be improved.