ZHEJIANG BHS JOURNAL BEARING CO.,LTD. located in FengXian District of ZheJiang, the company's brand "BHS", is a professional tilting pad thrust bearings manufacturers and Tilting pad bearings factory...

42CrMo belongs to the chromium-molybdenum series of ultra-high strength alloy steel. From the perspective of its composition, the carbon content is at a moderate level, which lays the foundation for its good comprehensive performance. The addition of chromium and molybdenum elements is the key to its excellent performance. The presence of chromium significantly improves the hardenability of the material, so that 42CrMo can obtain the expected structure and performance more evenly from the surface to the inside during the heat treatment process, effectively avoiding the problem of excessive difference in surface and internal performance caused by insufficient hardenability. The addition of molybdenum further enhances the strength and toughness of the material. The synergistic effect of the two gives 42CrMo a performance advantage far exceeding that of ordinary steel.

After quenching and tempering treatment, the performance of 42CrMo is further optimized and improved. During the operation of the vertical pump, the thrust bearing needs to withstand a variety of complex load conditions. When a large vertical pump starts, the powerful power will cause the bearing components to be subjected to a huge impact load. This instantaneous impact force is like a strong force suddenly applied, which is a great test for the impact resistance of the bearing material. The bearing components made of 42CrMo can effectively resist this impact with its excellent strength and toughness, minimize the impact of the impact force, and avoid deformation or even fracture of the material caused by the impact.

When the vertical pump stops running, a reverse impact load will also be generated. 42CrMo can still rely on its own performance to ensure the integrity of the bearing components. And during the continuous operation of the vertical pump, due to the difference in the characteristics of the conveying medium, such as the density and viscosity changes of the medium, and the pressure fluctuations during the conveying process, the bearing will be subjected to fluctuating loads. With its stable performance, 42CrMo can cope with these fluctuations well and will not easily suffer fatigue fracture due to changes in load. This effective response to complex and variable load conditions enables the bearing components made of 42CrMo to provide a stable and reliable basic structure for thrust bearings.

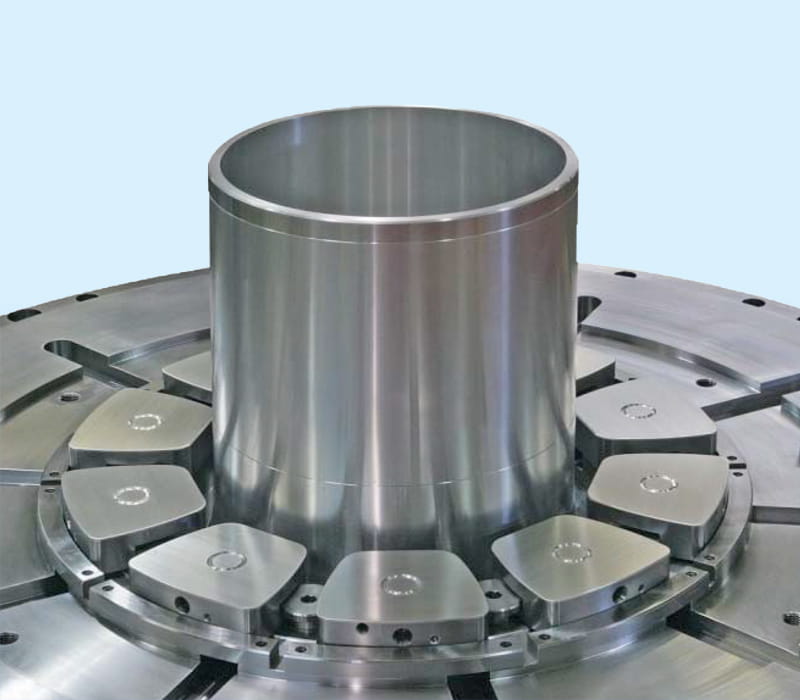

From the perspective of manufacturing technology, the good processing performance of 42CrMo also facilitates its wide application in thrust bearing manufacturing. In the forging process, 42CrMo can be forged within a suitable temperature range. Through multiple upsetting and drawing, it can refine the internal grains, eliminate the defects that may exist in the raw materials, and significantly improve the density of the material, laying a solid foundation for subsequent processing and use. In the machining process, whether it is turning or grinding, 42CrMo can adapt to the processing requirements well, and can be accurately processed into various shapes and sizes that meet the design requirements to meet the manufacturing needs of the complex structure of the thrust bearing.

In the field of practical application, thrust bearings made of 42CrMo have excellent performance. In the energy industry, vertical pumps are widely used in oil extraction, coal transportation and other links. In the process of oil extraction, vertical pumps need to extract crude oil from deep underground and transport it to the ground. In this process, the thrust bearing not only has to bear the weight of the pump's own rotating parts, but also has to deal with the axial force and radial force generated during the crude oil transportation process. Thrust bearings made of 42CrMo, with their high strength and high toughness, can operate stably for a long time under such harsh working conditions, ensuring the continuity of crude oil extraction.

In the chemical industry, vertical pumps are used to transport various chemical media with corrosive, flammable and explosive properties. Although other corrosion-resistant materials are used for protection in some parts that come into contact with corrosive media, 42CrMo, as the base material of the thrust bearing, still plays a key supporting role. Its good mechanical properties can ensure that the bearing maintains structural stability when it is subjected to additional pressure and torque brought by the medium, and will not deform due to external forces, thereby ensuring the normal operation of the pump and preventing production accidents and safety hazards caused by bearing failure.

In water conservancy projects and urban water supply systems, vertical pumps are responsible for lifting and transporting large amounts of water resources. These pumps often need to run continuously for a long time, and the reliability requirements for thrust bearings are extremely high. Thrust bearings made of 42CrMo, with their stable performance and long service life, can always maintain good working conditions during long-term operation, reduce the frequency of equipment maintenance and replacement, reduce operating costs, and provide strong guarantees for the normal water supply and stable operation of water conservancy projects in cities.

With the continuous development of industrial technology, the performance requirements for Vertical thrust bearings are also increasing. Although 42CrMo already has excellent performance, researchers and engineers are still exploring and researching it, further tapping its performance potential through surface treatment and compounding with other materials.