Does the load rating of the blower bearing need to be able to withstand the load generated during the operation of the blower?

The load rating of the

blower bearing needs to be able to withstand the load generated by the blower during operation. Blower usually generates large radial and axial forces, and the bearings need to be able to withstand these loads and maintain stable operation. The manufacturer determines the bearing's load rating through calculations and testing to ensure it can meet the blower's operating requirements. When the rated load of the bearing cannot meet the working requirements of the blower, problems such as bearing overload or damage may occur, affecting the normal operation of the blower.

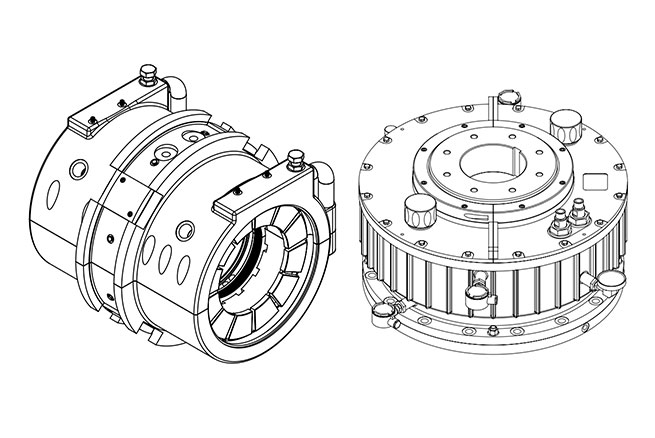

A blower is a device used to transport, pressurize or pump gas. They are widely used in industrial production, such as mining, steel, chemical industry and other fields, playing a key role. During the operation of the blower, large loads will be generated, including radial force and axial force.

Radial force is a force perpendicular to the axis direction, acting on the outer ring of the bearing. It is caused by the effect of the airflow generated by the blades of the blower on the outer ring. Axial force is a force parallel to the axis, acting in the axial direction of the bearing. It is primarily caused by the blower's thrust device or wheel design.

In order to ensure the stable operation and life of the blower, the bearings need to be able to withstand these loads. Manufacturers usually calculate and test the rated load capacity of bearings based on the design parameters of the blower. The rated load is the maximum load that the bearing can bear, generally expressed in terms of dynamic load or static load.

Dynamic load refers to the load borne by the bearing during rotation, which is composed of radial force and axial force. Static load refers to the load borne by the bearing when it is stopped or stationary, and generally only has radial force.

Manufacturers perform precise calculations and testing to determine the bearing's load rating to ensure it can meet the blower's operating requirements. This ensures that the blower will not suffer from bearing overload or damage during long-term operation.

Sometimes the operating requirements of the blower may exceed the rated load capacity of the bearings, perhaps because the blower requires greater flow or higher pressure. In this case, the manufacturer may take other steps to solve the problem, such as increasing the size of the bearings or using more wear-resistant materials.

The load rating of the blower bearing needs to be able to withstand the load generated during the operation of the blower. Manufacturers determine the bearing's load rating through calculations and testing to ensure it can meet the blower's operating requirements. When the rated load of the bearing cannot meet the working requirements of the blower, problems such as bearing overload or damage may occur, affecting the normal operation of the blower.

Based on the working requirements of the blower, what properties should we consider when choosing bearings?

The working requirements of the blower need to take into account the required air volume and pressure, which is mainly achieved through the rotation speed of the blower bearing. Blower usually needs to rotate at high speed to generate sufficient air volume and pressure, so bearings with sufficiently high rotational speed must be selected.

When selecting a blower bearing, you first need to consider whether the maximum speed of the bearing meets the required speed of the blower. If the maximum speed of the bearing is lower than the required speed of the blower, the bearing will wear prematurely, affecting the performance and life of the blower. Therefore, when purchasing bearings, you need to ensure that their maximum speed can meet the working requirements of the blower.

In addition, in addition to the maximum speed, the load capacity of the bearing should also be considered. Blower usually bears a large load during operation, so it is crucial to choose bearings with sufficient load capacity. If the load capacity of the bearing is insufficient, it will cause premature wear or even damage of the bearing, which will affect the normal operation of the blower.

In addition, the sealing performance of the bearing also needs to be considered. Blower usually works in harsh environments and may be affected by dust, moisture, etc., so it is very important to choose bearings with good sealing performance. Good sealing performance can effectively prevent dust and moisture from entering the inside of the bearing, reducing bearing wear and risk of failure.

According to the working requirements of the blower, we need to choose bearings with sufficiently high rotation speed, load capacity and sealing performance. Only when the bearings meet these requirements can the blower work properly and its performance and life can be guaranteed.