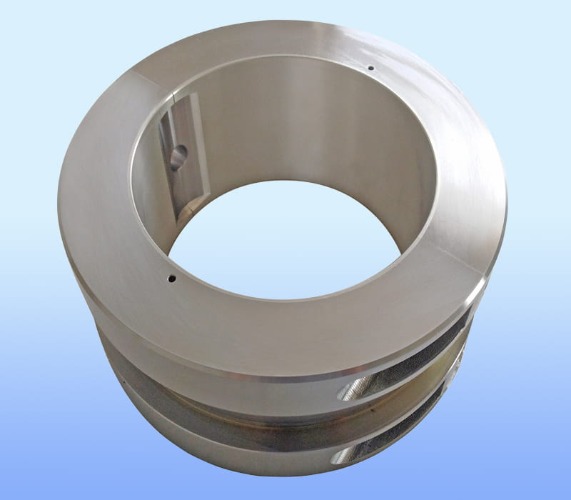

ZHEJIANG BHS JOURNAL BEARING CO.,LTD. located in FengXian District of ZheJiang, the company's brand "BHS", is a professional tilting pad thrust bearings manufacturers and Tilting pad bearings factory...

In industrial machinery, gearbox bearings are crucial components that ensure smooth operation by supporting rotating shafts and reducing friction. However, in applications involving continuous or high-load operations, gearbox bearings can face thermal challenges due to the friction generated. Overheating can premature bearing failure, which compromises machinery performance and increases maintenance costs.

A gearbox bearing is designed to support the shaft in rotating equipment, reduce friction, and bear the load. In continuous operations, gearbox bearings endure significant mechanical stress, which results in heat generation. Effective thermal management is essential to maintain the stability of the bearing’s performance.

Thermal management in gearbox bearings involves controlling the temperature to prevent damage caused by excessive heat. High temperatures can cause bearing materials to soften, resulting in wear, reduced performance, and even complete failure. Therefore, understanding the importance of maintaining proper thermal conditions is vital for the longevity of gearbox bearings.

Several factors affect the thermal behavior of gearbox bearings:

Load on the Bearing: Heavier loads generate more friction and, consequently, more heat. The higher the load, the greater the heat buildup in the bearing.

Speed of Operation: Higher rotational speeds increase the bearing’s friction, which results in more heat. Bearings used in high-speed operations require more efficient cooling and heat dissipation.

Lubrication: Lubricants play a key role in reducing friction and, thus, controlling heat. The type and quality of lubrication affect the thermal performance of gearbox bearings.

Bearing Materials: The material composition of the bearing affects its ability to withstand high temperatures. Bearings made of materials with poor thermal conductivity tend to retain heat, which can result in potential overheating.

Ambient Temperature: The surrounding environment influences the temperature of the gearbox. High ambient temperatures may limit the ability of the bearings to dissipate heat.

To effectively manage heat in gearbox bearings, several techniques and strategies can be applied:

Lubrication is the line of defense in controlling friction and heat generation. An optimized lubrication system ensures that the bearings receive adequate lubrication, reducing the heat caused by friction. The type of lubricant used—whether grease, oil, or synthetic fluids—should be selected based on the operating conditions. Regular monitoring and replenishment of lubrication help maintain consistent performance and prevent overheating.

Oil Circulation: A forced oil circulation system can help in removing heat generated by the bearings. This system pumps oil through the bearing and gearbox, aiding in heat transfer and cooling.

Temperature-Activated Lubricants: Lubricants that adapt to temperature changes can also help in providing lubrication at varying operating conditions.

In high-speed or high-load applications, relying solely on lubrication may not be enough. Cooling systems that actively reduce the temperature in the bearing area are often necessary. Common approaches include:

Air Cooling: A simple method where air is circulated around the gearbox to lower the temperature. Fans or ventilation ducts are typically used in industrial settings.

Liquid Cooling: More advanced systems involve circulating a coolant through the gearbox to absorb and transfer heat away from the bearings. These systems are especially useful in high-power, high-speed applications.

Heat Exchangers: Heat exchangers can be installed to transfer excess heat from the bearings to an external fluid, which then carries it away from the gearbox.

In cases where ambient temperatures are high, or cooling systems are insufficient, the use of thermal insulation can help. Insulation materials can be placed around the bearing housing to prevent external heat sources from affecting the gearbox bearings.

Choosing the right bearing material can improve the thermal management of gearbox bearings. Materials with better thermal conductivity or heat resistance, such as ceramic or hybrid bearings, may help in reducing heat buildup. The right material ensures that heat is evenly distributed across the bearing, minimizing localized overheating.

Routine monitoring of gearbox temperature and bearing performance is essential. Temperature sensors can be installed to detect excessive heat. If temperatures exceed recommended limits, maintenance or replacement can be scheduled before failure occurs.

Infrared Thermography: Non-contact infrared thermography is a method used to monitor surface temperature variations and detect hot spots in real-time.

Vibration Analysis: Excessive heat can alter the behavior of bearings, causing increased vibrations. Vibration monitoring tools can provide early warning signs of thermal degradation.

Advanced Techniques: Active Thermal Management

Some modern systems incorporate active thermal management technologies, such as:

Electrohydrodynamic Cooling: A technique that uses electric fields to enhance the heat transfer rate in the lubricant, improving cooling performance.

Phase Change Materials (PCMs): PCMs absorb heat when the temperature exceeds a certain threshold and release it once the temperature drops, providing a self-regulating thermal management solution.

In specialized gearbox applications, such as those in the aerospace or heavy machinery industries, more complex thermal management solutions are required. These may include advanced liquid cooling systems, enhanced heat sinks, and integrated thermal shields that protect sensitive bearings from temperatures.

| Method | Description | Application Area |

|---|---|---|

| Optimized Lubrication | Ensures proper lubrication to reduce friction and heat buildup. | High-speed and heavy-load gearboxes |

| Air Cooling | Circulates air around the gearbox to cool the bearings. | Standard industrial applications |

| Liquid Cooling | Circulates coolant to absorb and transfer heat away from bearings. | High-speed and power-heavy applications |

| Thermal Insulation | Prevents external heat sources from affecting the gearbox. | High-temperature environments |

| Bearing Material Selection | Choosing materials with better thermal conductivity or resistance. | Aerospace and high-performance gearboxes |

Thermal management in gearbox bearings is crucial to maintaining the performance, longevity, and reliability of industrial machinery under continuous operation. By optimizing lubrication, implementing effective cooling systems, choosing the right bearing materials, and maintaining a regular monitoring routine, businesses can reduce the risks of overheating and ensure that gearbox bearings operate within safe thermal limits.

1. What is the impact of high temperatures on gearbox bearings?

High temperatures can reduced bearing life, excessive wear, and even failure due to material degradation and increased friction.

2. Why is lubrication important for thermal management in gearbox bearings?

Lubrication reduces friction between moving parts, lowering the heat generated during operation and ensuring smoother performance.

3. What are the benefits of liquid cooling in gearbox bearings?

Liquid cooling helps transfer heat away from bearings more effectively, making it ideal for high-load and high-speed applications.

4. How often should gearbox bearings be inspected for thermal performance?

Bearings should be inspected regularly for temperature and vibration issues, with checks conducted at least once a month for continuous operations.

5. What bearing materials are for thermal management?

Ceramic or hybrid bearings are for thermal management due to their higher thermal conductivity and heat resistance compared to traditional materials.