Tilting pad thrust pump bearings are a type of hydrodynamic bearing that is commonly used in centrifugal pumps to support axial loads. They are designed to handle high loads and provide long service life. The unique design of tilting pad thrust bearings allows for a higher load capacity and greater stability compared to other types of bearings.

Functionality:

The basic functionality of a tilting pad thrust bearing is to support a thrust load. Thrust loads are axial loads that are perpendicular to the axis of rotation. In a centrifugal pump, the impeller rotates on a shaft and generates a thrust load that is transmitted through the shaft to the thrust bearing. The tilting pad thrust bearing supports this thrust load by creating a wedge-shaped film of oil that lifts the pads off the bearing surface. The wedge-shaped film of oil creates a hydrodynamic pressure that counteracts the thrust load and supports the shaft.

Design:

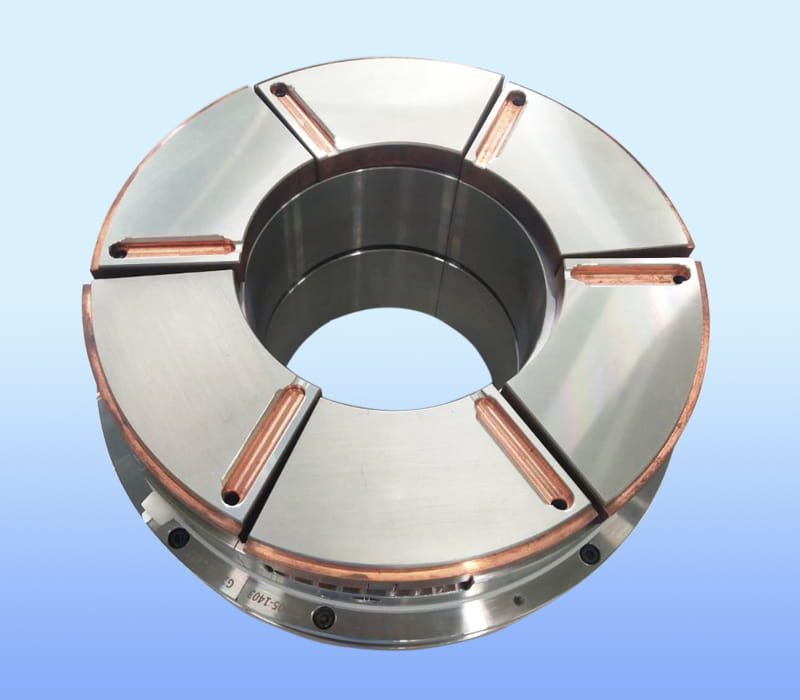

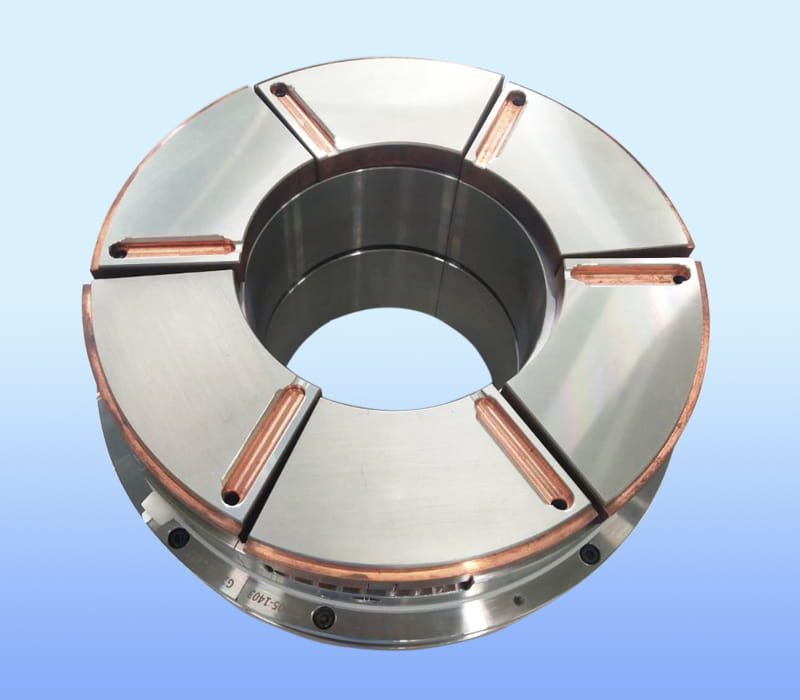

Tilting pad thrust bearings are designed with a series of pads that are arranged in a circle around the shaft. Each pad is mounted on a separate pivot that allows it to tilt in response to changes in load. The pads are typically made of a low-friction material such as bronze or babbitt that allows them to slide easily on the bearing surface.

The tilting action of the pads is critical to the operation of the bearing. As the shaft rotates, the thrust load causes the pads to tilt forward in the direction of rotation. This tilting action creates a wedge-shaped film of oil that lifts the pads off the bearing surface. The oil film is thicker at the leading edge of the pad and thinner at the trailing edge. This wedge-shaped film of oil creates a hydrodynamic pressure that counteracts the thrust load and supports the shaft.

Advantages:

Tilting pad thrust bearings offer several advantages over other types of bearings. The primary advantage is their ability to handle high thrust loads. The tilting action of the pads allows for a larger contact area between the bearing surface and the pads. This larger contact area results in a higher load capacity and greater stability.

Another advantage of tilting pad thrust bearings is their long service life. The design of the bearing allows for a continuous supply of oil to the bearing surface. This oil film reduces friction and wear on the bearing surface, which extends the life of the bearing.

Tilting pad thrust bearings are a critical component in centrifugal pumps. They provide the support necessary to handle high thrust loads and ensure the smooth operation of the pump. The unique design of tilting pad thrust bearings allows for a higher load capacity and greater stability compared to other types of bearings. This, in turn, results in a longer service life and reduced maintenance costs for the pump.