ZHEJIANG BHS JOURNAL BEARING CO.,LTD. located in FengXian District of Shanghai, the company's brand "BHS", is a professional tilting pad thrust bearings manufacturers and Tilting pad bearings factory...

Kingsbury type of Equalizing thrust bearing

Sizes: 3inch-36inch

Pads number: 4-pad,6-pads,8-pad,9-pad,11-pad,14-pad

Max Linear speed: 120m/s

Speed range: 1000rpm-25000rpm

Max thrust load: 150Tons

Material: 42CrMo+Babbitt/Cu-Cr+Babbitt

Compact design with LEG

Good performance of dissipation,lower temperature rise

Babbitt(Tego star 738) comply with Europe REACH requirements

Use in water feeding pump,neuclear pump,mult-stage pump(BB3,BB5),turbines,compressor.

E-mail : [email protected] Tilting pad thrust bearings including equalizing type and non-equializing type, transmits axial shaft loads into the foundation or machine support of rotating apparatus. The equalizing thrust bearing actually transmits the load through a self-renewing film of oil during operation and an unique force-balancing action distributes the load across the shoes.Working surfaces touch each other only during start-up and shut-down.Otherwise,these surfaces are separated by the fluid film,so surface wear is minimal,and bearing life dramatically lengthened.

Our tilting pad thrust bearings offers many operating advantages,including:

• Excellent shock absorbing capacity

• Superior damping characteristics

• Life span equal to that of the machine

• Versatility in application

• Performance monitoring capability

The thrust bearings have been designed to be used with many types of machines or applications.The thrust shaft can rotate clock-wise or counterclockwise,or bidirectionally,if necessary.These bearings can be used with almost any type of oil,and,due to the equalizing capability of the bearings,only reasonable care has to be taken in assembly to assure that the bearings are aligned properly.We manufacture many of these bearings in sufficient quantities to provide economical advantages to the users,and we have been stocking almost all range of the thrust pad bearings in our warehouse.

Professional R&D team

1.The professional development team---Bearing experts from domestic and abroad;

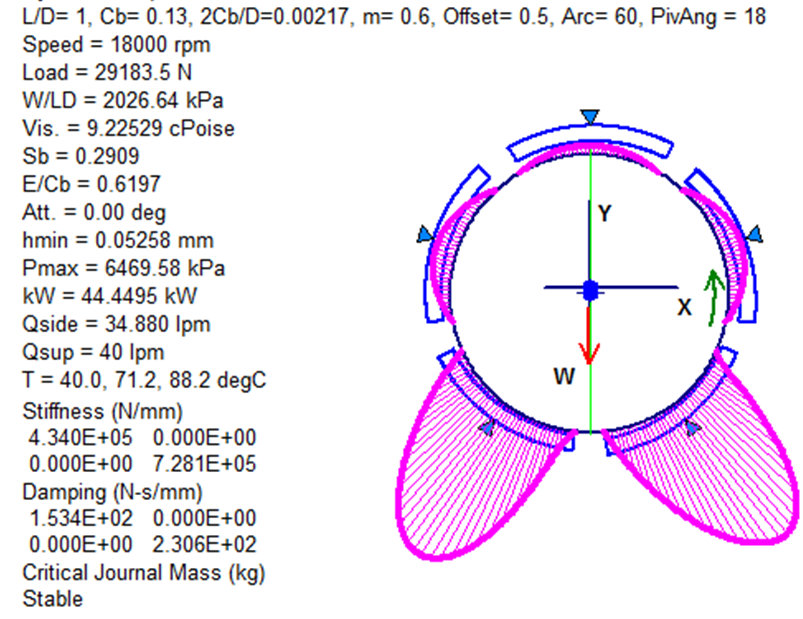

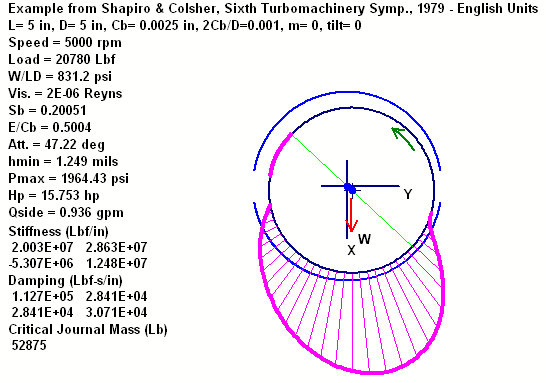

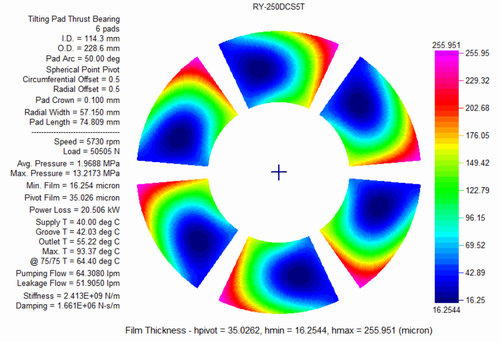

2.Advanced computing software----The static/dynamic performance calculation and analysis,such as oil film thickness, damping,stiffness, temperature/pressure distribution,power loss,oil quantity.etc.;

3.Advanced product development platform-SOLIDWORKS,CAD, CAE, CFD and other softwares to virtual prototype design (accurate, efficient and cost savings);

4.Strong technical support team-Slide bearing R&D institute of ShangHai Jiao Tong university;

5.It has more than 50 patents, including more than 10 invention patents.

Advanced and Accurate Calculation, Analysis

|

|

|

| Tilting pad bearing analysis | Plain bearing analysis | Thrust pad bearing analysis |

Testing Equipments

|

|

| Journal bearing heavy load test | Whitematerial (polymers) bonding test |

|

|

| Babbitt alloy friction and fatigue test | Water lubrication bearings test |

Zhejiang BHS Journal Bearing Co., Ltd. is a professional Tilting pad thrust bearings Manufacturers and Tilting pad thrust bearings factory, has been focusing on slide bearing’s design, manufacture, experiment and fault diagnosis for many years, BHS has become an excellent supplier of solutions for sliding bearing systems in China.

The company has more than 50sets of precision CNC machining center, Babbitt alloy casting equipment, Babbitt alloy sprayer, heat treatment, and other equipment. The annual production capacity of 26,000 sets of slide bearings. Through continuous technological research, the company has the ability to manufacture various types of slide bearings.

Our company approved by ISO:9001-2015, ISO:14001-2015, ISO:45001-20018, Standardization Safty production Certificate, National High-Tech Enterprise certificate, Provincial High-Tech Enterprise certificate, Military supplier certificate and variety of patents 30 kinds.