A

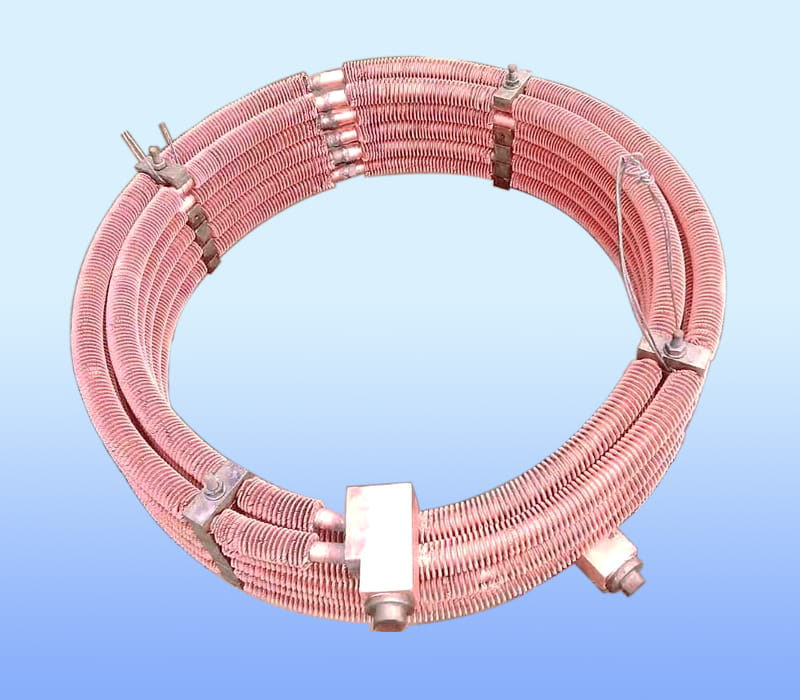

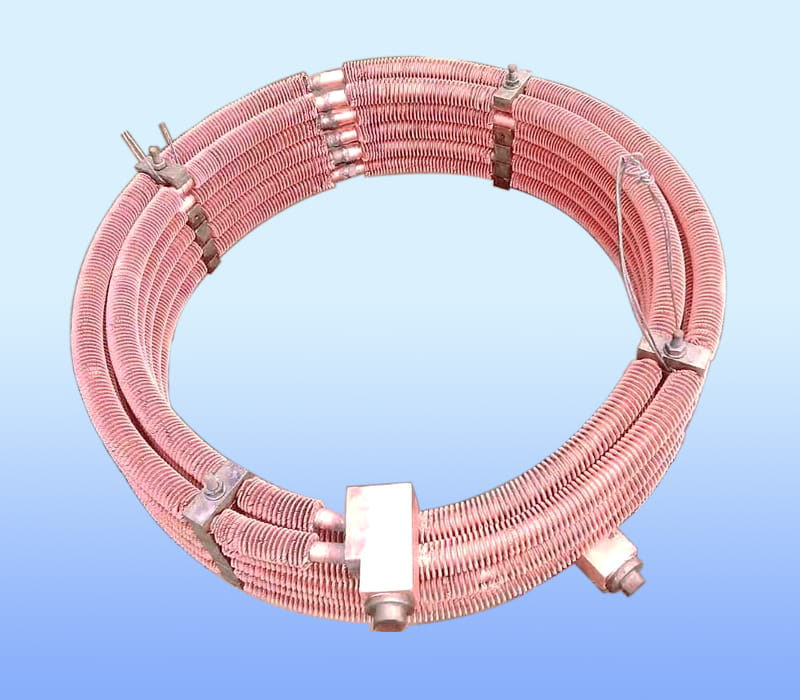

THRUST BEARING OIL COOLER is a heat exchanger that provides cooling for lubricant used in thrust bearings. Cooling is needed because a lubricating system can become overheated when the thrust bearings rotate within the sump.

The most common coolers are manufactured using 90/10 Cu/Ni copper finned tubes. Units can be manufactured with bare tube or soldered fin-to-tube connections.

Temperature control

The THRUST BEARING OIL COOLER can be fitted with a THERMA-SENTRY to sense the actual bearing temperature. If this is specified, the thermistor will send an impulse to a monitoring device provided by the customer.

High temperatures and high loads in thrust bearing applications may lead to shear thinning or cavitation of the lubricant film. The latter can reduce the load capacity of the bearing, degrade the lubricant properties and increase the wear rate.

Optimal pocket designs are important in this respect. Detailed numerical simulations for thrust bearing applications must be performed to optimize the design of the oil film.

The ITEX type exchanger technology, which uses gasketed plate and frame, is an efficient heat exchanger that is easy to clean and allows for a modular cooling capacity. However, this technology requires a more elaborate filtration system in order to avoid clogging the heat exchanger.

Leakage detection

The THRUST BEARING OIL COOLER is designed with leak detection features, available in both conventional and Leak Detector design (both including double tubesheet construction). In the event of a water leak, the water is directed to a water-filled detection chamber that is quickly detected.

The cooler is also available with a leak detector feature that ensures the safety of the transformer by preventing the mixing of water and oil in the event of a leak, which would potentially lead to contamination. Using a double tube configuration, grooves are positioned between the inner and outer tubes to prevent contaminating of the oil with water.

As the bearing load capacity of power stations is increasing, there are concerns over oil mist leakage in some hydropower stations [5,6]. The lubricating oil is a mixture of different chemical components and has different volatilities. The centrifugal force of the oil during high-speed operation converts substantial mechanical into heat energy. The accumulated heat may cause the bushing bearing to fail, resulting in oil mist leakage.

Oil filtration

Oil filtration reduces the temperature of oil, thus extending positively bearing and gear life. It also prevents the deterioration of lubricating oil and the erosion of components.

The oil filtration system can be used on small or large guide and thrust bearings. Depending on the application, it can be combined with an oil circulation lubrication system.

Especially for large bearings, it is possible to install an oil filtration system with a double tube configuration. This allows the detection of water leakages in case of a ruptured tube.

This double tube configuration is based on grooves that are positioned between the two tubes. If one of the tubes leaks, the liquid is quickly detected and transported to a drip pan.

The oil filtration system is protected by a bypass valve. This ensures that the mechanical pump can be operated in case of a blocked filter. This feature is necessary to avoid oil starvation of the engine.

Material selection

The THRUST BEARING OIL COOLER boasts a few well chosen ingredients including a cleverly concealed fan, a top of the line heat exchanger and the latest in lubricant evaporation technology. Featuring a full suite of safety features, this cooler is as good as it gets.

Using a patented design that is simple to operate and maintain, we are proud to offer our customers the latest and greatest in oil cooling and lubrication technology. Designed to outperform the competition in any environment, our products offer a variety of solutions to meet your specific needs. From our most popular line of oil cooled bearings to the most complex designs, our seasoned engineers have the tools and know how to ensure your machine performs as it was meant to.

We are the go to provider of high quality products and the best customer service in the industry. Whether you need help with the latest cutting edge technologies or just want to discuss your current cooling solution, our friendly team is here to help.