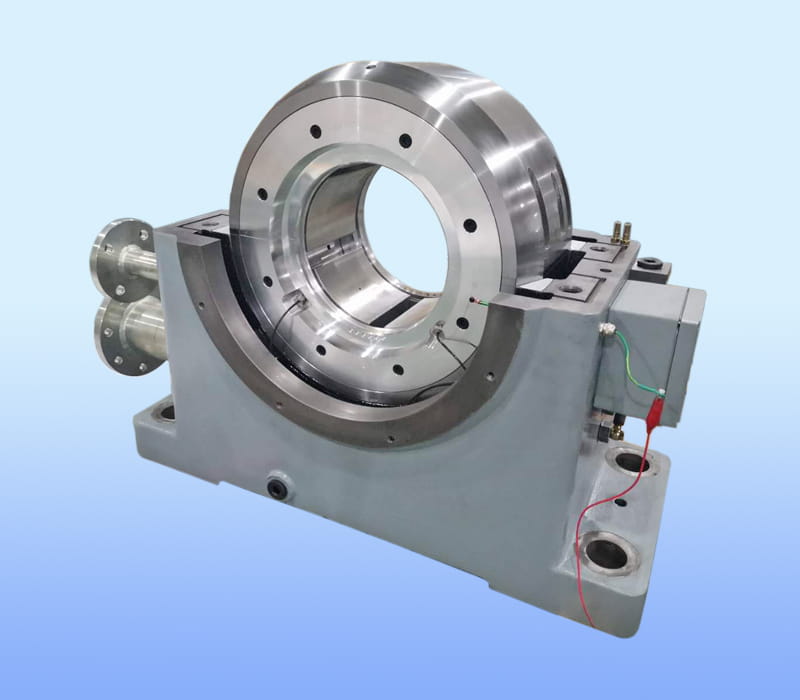

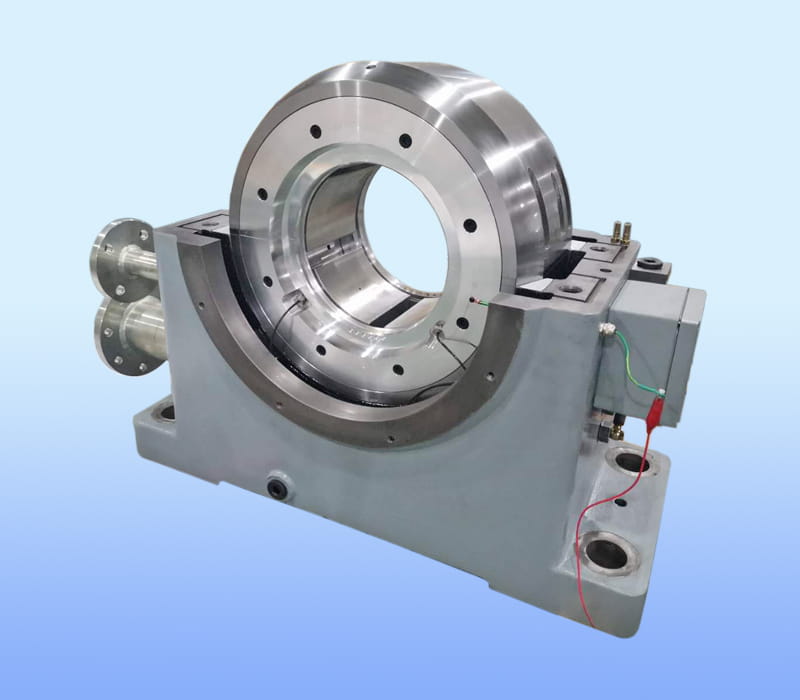

Blower pedestal slide bearings are a critical component of many types of industrial and commercial blowers. These bearings provide support and stability to the blower shaft, ensuring that it operates smoothly and efficiently. In this article, we will take a closer look at blower pedestal slide bearings, how they work, and their importance in blower operation.

What are Blower Pedestal Slide Bearings?

Blower pedestal slide bearings are a type of bearing designed to support the shaft of a blower. They are typically used in large, high-capacity blowers that are used in industrial and commercial applications. These bearings are designed to handle high loads and provide low-friction support for the blower shaft.

Blower pedestal slide bearings are typically made from materials such as bronze, aluminum, or stainless steel. They are designed with a sliding contact surface that allows the blower shaft to rotate smoothly and without excessive friction. The sliding surface of the bearing is typically coated with a lubricating oil or grease to further reduce friction and wear.

How do Blower Pedestal Slide Bearings Work?

Blower pedestal slide bearings work by providing support and stability to the blower shaft. As the blower shaft rotates, it places a load on the bearings. The bearings are designed to handle this load and provide a low-friction surface for the shaft to rotate on.

The sliding contact surface of the bearing is typically coated with a lubricating oil or grease. This helps to reduce friction between the shaft and the bearing, which can lead to wear and damage over time. The lubricant also helps to dissipate heat generated by the rotating shaft, which can help to prevent overheating and premature failure.

Why are Blower Pedestal Slide Bearings Important?

Blower pedestal slide bearings are an essential component of many types of industrial and commercial blowers. They provide critical support and stability to the blower shaft, ensuring that it operates smoothly and efficiently. Without these bearings, the blower shaft would be subject to excessive friction and wear, which could lead to premature failure.

In addition to providing support and stability to the blower shaft, slide bearings also help to reduce noise and vibration. As the blower shaft rotates, it can generate a significant amount of noise and vibration. The low-friction surface provided by the slide bearings helps to dampen this noise and vibration, making the blower operation quieter and smoother.