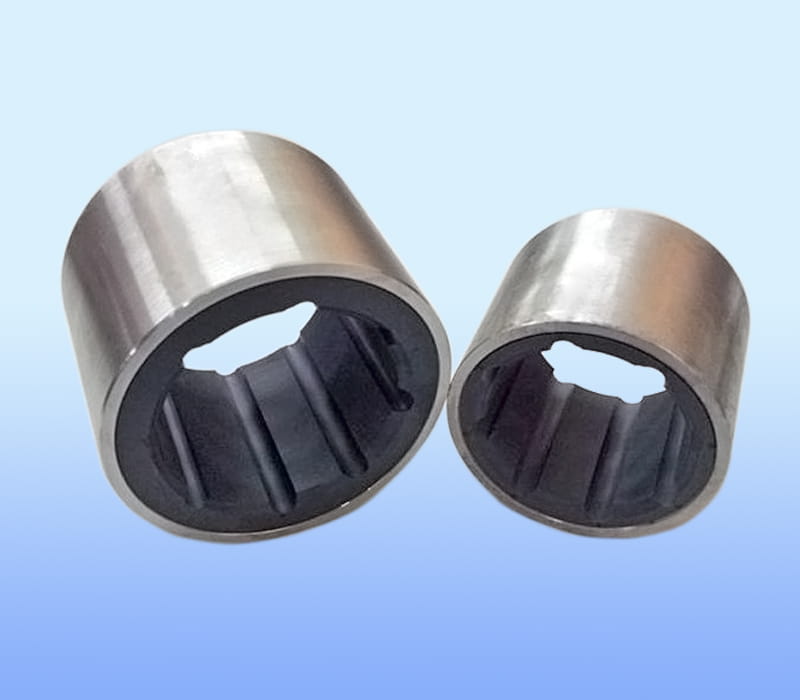

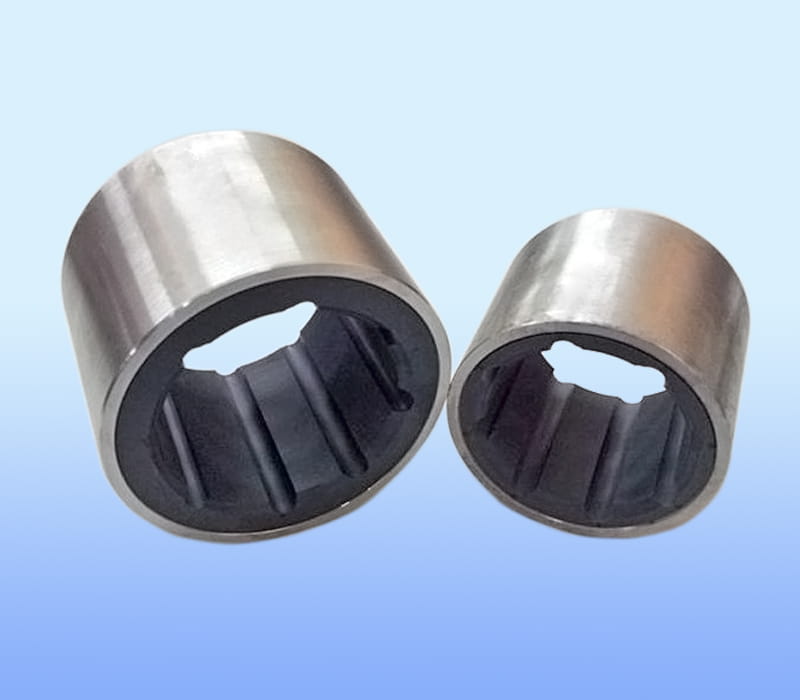

PTFE AND PEEK BEARINGS are essential components used in various industries to enable smooth rotation and reduce friction between moving parts. Among the many types of bearings available, those made from polytetrafluoroethylene (PTFE) and polyetheretherketone (PEEK) have gained significant attention due to their unique properties and exceptional performance in demanding applications. In this article, we will delve into the advantages of PTFE and PEEK bearings, highlighting their characteristics, applications, and benefits.

Polytetrafluoroethylene (PTFE) Bearings:

Polytetrafluoroethylene, commonly known as PTFE, is a synthetic fluoropolymer that possesses remarkable properties suitable for bearing applications.

a. Low Friction and Self-Lubrication:

PTFE bearings exhibit an exceptionally low coefficient of friction, which results in reduced energy consumption and enhanced efficiency. They have excellent self-lubricating properties, eliminating the need for additional lubrication in many cases.

b. Chemical Resistance:

PTFE is highly resistant to chemicals, acids, and corrosive substances, making it an ideal choice for bearings used in harsh environments. This resistance ensures the longevity and reliability of PTFE bearings.

c. Wide Temperature Range:

PTFE bearings can withstand a broad temperature range, from extremely low temperatures to high heat environments, without compromising their performance. This versatility enables their use in diverse industrial applications.

d. Dimensional Stability:

PTFE exhibits excellent dimensional stability, maintaining its shape and structure even under heavy loads and high-speed rotation. This property makes PTFE bearings suitable for precision applications.

Polyetheretherketone (PEEK) Bearings:

Polyetheretherketone, known as PEEK, is a high-performance thermoplastic polymer that offers several advantages for bearing applications.

a. High Mechanical Strength:

PEEK bearings possess exceptional mechanical strength, allowing them to withstand heavy loads and high-speed rotation. They exhibit minimal deformation, ensuring long-lasting and reliable performance.

b. Excellent Wear Resistance:

PEEK bearings have excellent wear resistance, making them suitable for applications involving abrasive environments and high levels of friction. They maintain their performance and durability over extended periods, reducing maintenance requirements.

c. Dimensional Stability at Elevated Temperatures:

One of the key advantages of PEEK bearings is their dimensional stability even at elevated temperatures. They can maintain their shape and functionality under continuous use in high-temperature environments, providing consistent performance.

d. Chemical Compatibility:

PEEK exhibits excellent chemical compatibility with a wide range of substances, including acids, bases, solvents, and lubricants. This compatibility ensures the longevity and reliability of PEEK bearings in various industrial settings.

Applications of PTFE and PEEK Bearings:

PTFE and PEEK bearings find applications in numerous industries, including:

a. Automotive: PTFE and PEEK bearings are used in automotive components such as suspension systems, engine parts, and gearbox assemblies, providing durability, reduced friction, and improved performance.

b. Aerospace: These bearings are utilized in aircraft systems, landing gears, control surfaces, and engine components due to their ability to withstand high temperatures, extreme conditions, and corrosive environments.

c. Medical: PTFE and PEEK bearings are employed in medical devices and equipment, including surgical instruments, prosthetics, and implantable devices, thanks to their biocompatibility, chemical resistance, and low friction properties.

d. Industrial Machinery: PTFE and PEEK bearings are utilized in various industrial machinery applications, such as pumps, valves, conveyors, and textile machinery, offering reliability, longevity, and efficient operation.