Compressors play a crucial role in various industries, such as oil and gas, petrochemical, and power generation, where they are used to increase the pressure of a gas or vapor. These machines operate at high speeds and under demanding conditions, requiring robust and efficient bearing systems to ensure their reliable and continuous operation. One such bearing system commonly employed in compressors is the tilting pad journal bearing.

Understanding Tilting Pad Journal Bearings

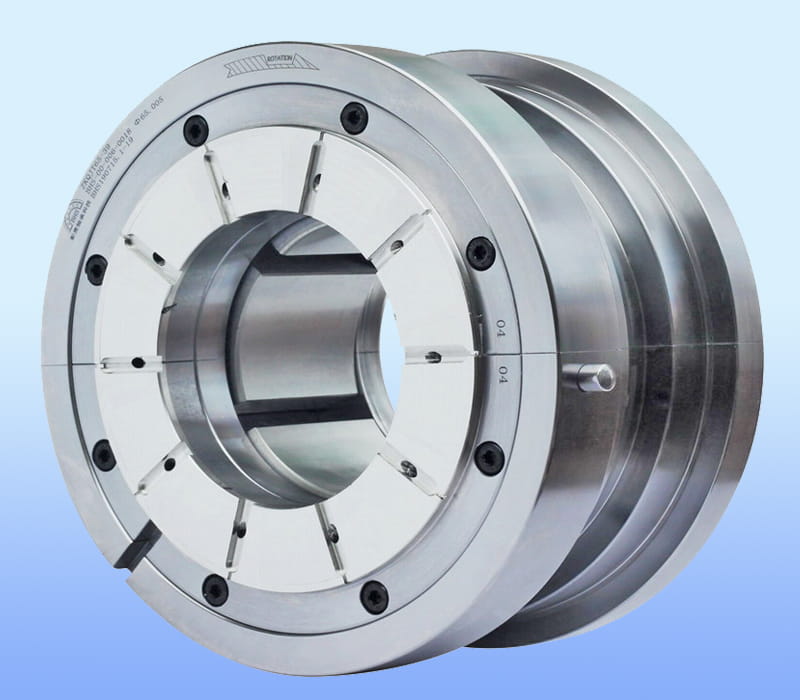

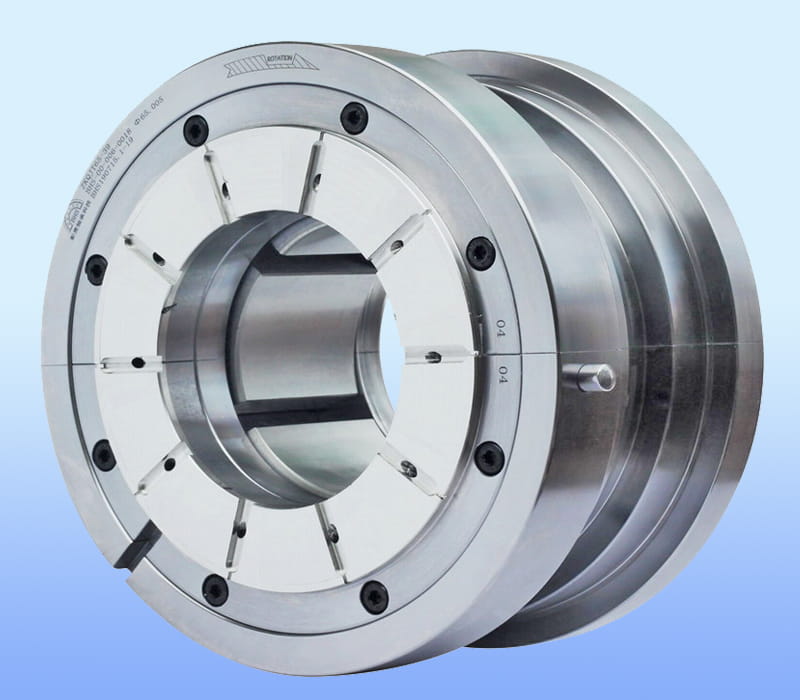

A tilting pad journal bearing is a type of hydrodynamic bearing that supports the rotating shaft of a compressor. It consists of multiple pads arranged circumferentially around the shaft and supported by a stationary housing. Each pad is capable of tilting dynamically as the shaft rotates, allowing for the formation of a pressurized fluid film between the pads and the shaft surface. This fluid film separates the pad and the shaft, preventing direct contact and minimizing friction, wear, and heat generation.

Key Features and Benefits

Load Distribution: Tilting pad journal bearings excel in load distribution. The design allows for the individual tilting of each pad, adapting to varying loads and distributing them evenly across the bearing surface. This feature enhances the bearing's ability to handle high loads, reducing localized stresses and promoting extended operational life.

Stability and Vibration Control: The dynamic tilting action of the pads enhances the stability of the bearing system. As the rotor speed increases, the fluid film pressure between the pads and the shaft increases, providing additional stiffness and damping to counteract vibrations. This characteristic is particularly crucial in high-speed compressor applications, where minimizing vibrations is essential for reliable and efficient operation.

Lubrication and Cooling: The tilting pad design ensures effective lubrication and cooling of the bearing surfaces. The rotating shaft creates a pumping action, drawing lubricant into the bearing clearance. This hydrodynamic lubrication prevents metal-to-metal contact and reduces frictional losses, resulting in reduced power consumption and increased efficiency. Additionally, the fluid film also acts as a coolant, dissipating heat generated during operation.

Maintenance and Reliability: Tilting pad journal bearings are designed for easy maintenance. The individual pads can be removed and replaced without disassembling the entire bearing, simplifying inspection and repair procedures. This feature reduces downtime and improves overall system reliability.

Applications of Compressor Tilting Pad Journal Bearings

Compressor tilting pad journal bearings find widespread use in various industries, particularly in critical applications where reliability and performance are paramount. Some notable applications include:

Centrifugal Compressors: Centrifugal compressors are widely used in oil and gas, refineries, and chemical plants. The high rotational speeds and demanding operating conditions necessitate the use of advanced bearing systems such as tilting pad journal bearings to ensure reliable and efficient performance.

Process Gas Compressors: Process gas compressors are employed in gas treatment plants, LNG plants, and other industrial processes. Tilting pad journal bearings provide the necessary stability, load distribution, and cooling capabilities required for these demanding applications.

Turboexpanders: Turboexpanders are used in cryogenic applications for liquefaction of gases such as natural gas. The precise control and stability offered by tilting pad journal bearings make them an ideal choice for supporting the rotating shaft of turboexpanders.

Compressor tilting pad journal bearings play a vital role in ensuring the efficient and reliable operation of compressors in various industries. Their ability to distribute loads evenly, control vibrations, and provide effective lubrication and cooling contribute to improved performance and increased longevity of the bearing system. As technology continues to advance, further innovations in tilting pad journal bearing design and materials