ZHEJIANG BHS JOURNAL BEARING CO.,LTD. located in FengXian District of ZheJiang, the company's brand "BHS", is a professional tilting pad thrust bearings manufacturers and Tilting pad bearings factory...

There are many types of sliding bearings:

①According to the direction that can bear the load, it can be divided into two types: radial (centripetal) sliding bearings and thrust (axial) sliding bearings.

②According to the type of lubricant, it can be divided into 7 categories: oil lubricated bearings, grease lubricated bearings, water lubricated bearings, gas bearings, solid lubricated bearings, magnetic fluid bearings and electromagnetic bearings.

③According to the thickness of the lubricating film, it can be divided into two types: thin-film lubricated bearings and thick-film lubricated bearings.

④According to the bearing material, it can be divided into bronze bearings, cast iron bearings, plastic bearings, gem bearings, powder metallurgy bearings, self-lubricating bearings and oil-impregnated bearings.

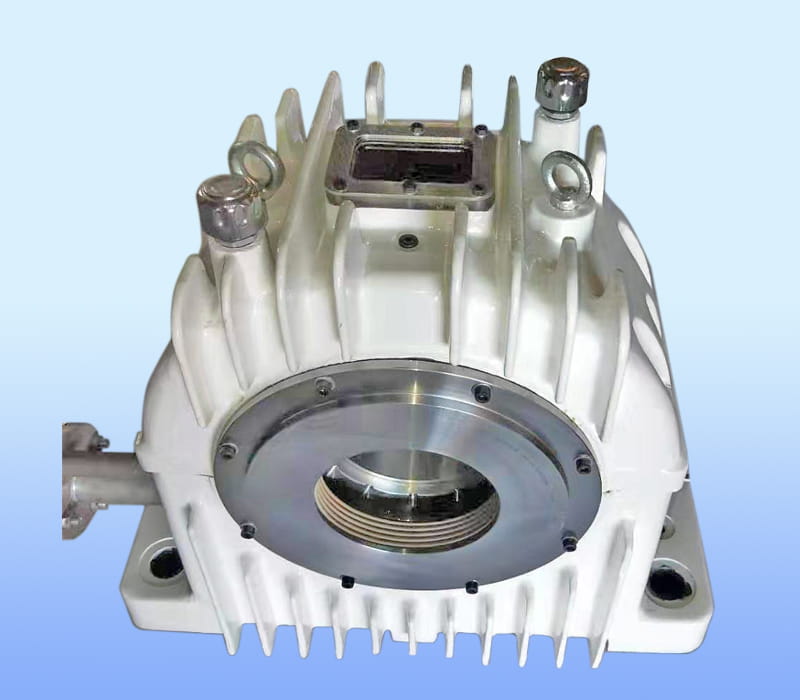

⑤According to the bearing structure, it can be divided into round bearing, elliptical bearing, three-oil-blade bearing, stepped surface bearing, tilting shoe bearing and foil bearing, etc.

Bearings are divided into split and integral structures. In order to improve the friction properties of the bearing bush, one or two layers of anti-friction materials are often cast on the inner diameter surface of the bearing bush, which is usually called a bearing bush. Therefore, the bearing bush has a bimetallic bush and a trimetal bush.

Bearing bushes or bearing linings are important parts of sliding bearings, and the materials of bearing bushes and bearing linings are collectively referred to as bearing materials. Because the bearing bush or bearing bush is in direct contact with the journal, the journal part is generally more wear-resistant, so the main failure mode of the bearing bush is wear.

The wear of the bearing bush is directly related to the material of the journal, the material of the bearing itself, the lubricant and the state of lubrication. These factors should be comprehensively considered when selecting the bearing material to improve the service life and working performance of the sliding bearing.

Production Method

Domestically, repair welding, bushing, pitting, etc. are generally used for sliding bearing wear. However, when the shaft is made of No. 45 steel (quenched and tempered), if only surfacing is used, welding will occur. Stress, under heavy load or high-speed operation, cracks and even fractures may appear at the shaft shoulder. If stress relief annealing is used, it is difficult to operate, and the processing cycle is long, and the maintenance cost is high; when the shaft is made of HT200 , The use of cast iron welding is not ideal. Some companies with higher maintenance technology will use brush plating, laser welding, micro-arc welding and even cold welding, etc. These maintenance technologies often require higher requirements and high costs.

For the above repair technology, it is not common in European, American, Japanese and Korean companies. Developed countries generally use polymer composite technology and nanotechnology. Polymer technology can be operated on-site, which effectively improves repair efficiency and reduces repair costs and repairs. strength.