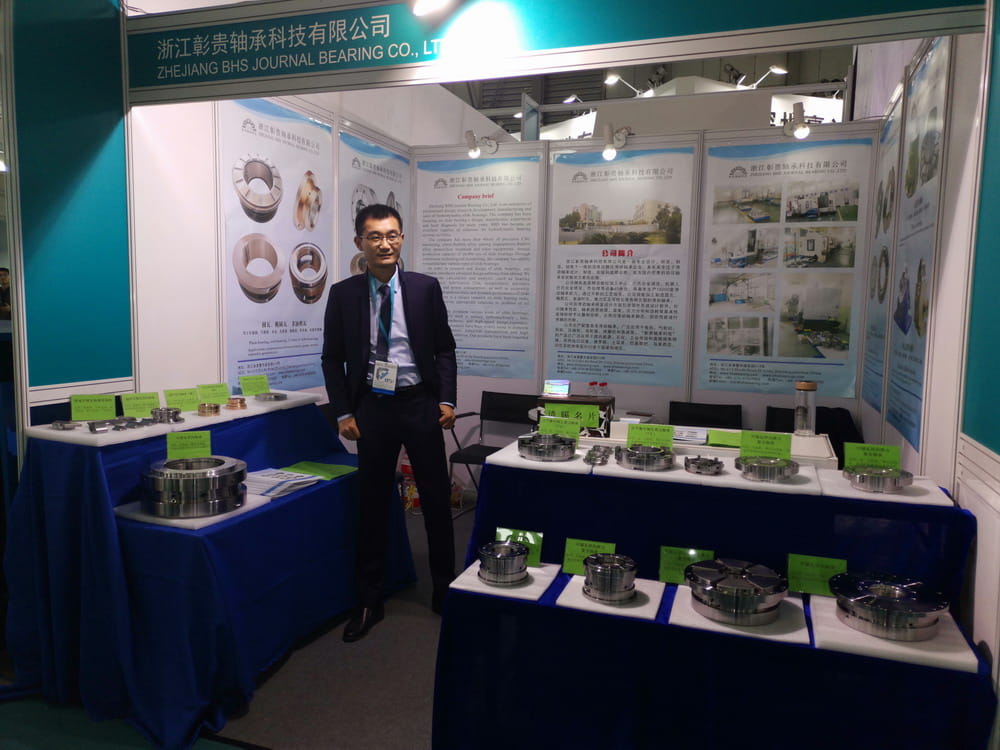

ZHEJIANG BHS JOURNAL BEARING CO.,LTD. located in FengXian District of ZheJiang, the company's brand "BHS", is a professional tilting pad thrust bearings manufacturers and Tilting pad bearings factory...

Outer spherical ball bearing

The outer diameter surface of the outer ring of the outer spherical ball bearing is a spherical surface, which can play a role in centering.

Spherical roller bearing

Spherical roller bearings have two rows of symmetrical spherical rollers, which mainly bear radial loads, and can also bear axial loads in any direction, but cannot bear pure axial loads. The outer ring raceway of this type of bearing is spherical, so it has good alignment performance and can compensate for coaxiality errors. The bearing can still be used normally when the shaft is bent or installed out of center. The alignment varies with the bearing size series. Generally, the allowable alignment angle is 1~2.5 degrees. This type of bearing has a large load capacity. In addition to the radial load, the bearing can also withstand the axial load acting in both directions. It has good impact resistance. In other words, the allowable working speed of the spherical roller bearing is relatively low. Suitable for working under heavy load or vibration load.

Flange bearing

Flange bearings are provided with flanged flanges on the outer wheel. The feature is that it can simplify the structure of the host, reduce the size of the host, and make the bearing easier to locate.

Bearing with seat

A component in which a radial bearing and a seat are combined. There is a base plate for mounting screws on a supporting surface parallel to the axis of the bearing.

Combined bearing

A rolling bearing composed of two or more bearing structures in a set of bearings at the same time. Such as needle roller and thrust cylindrical roller combined bearings, needle roller and thrust ball combined bearings, needle roller and angular contact ball combined bearings, etc.

Linear Bearings

Linear bearings are divided into metal linear bearings and plastic linear bearings.

Metal linear bearing is a linear motion system produced at low cost, used in conjunction with a cylindrical shaft with an infinite stroke. Since the bearing ball is in point contact with the shaft, the use load is small. The steel ball rotates with very little frictional resistance, so as to obtain high-precision smooth movement.

Plastic linear bearings are a kind of linear motion system with self-lubricating characteristics. The biggest difference from metal linear bearings is that metal linear bearings have rolling friction, and the bearing and cylindrical shaft are in point contact, so this is suitable for low-load and high-speed motion; Plastic linear bearings are sliding friction, and there is surface contact between the bearing and the cylindrical shaft, so this is suitable for high-load, low-speed movement.