ZHEJIANG BHS JOURNAL BEARING CO.,LTD. located in FengXian District of ZheJiang, the company's brand "BHS", is a professional tilting pad thrust bearings manufacturers and Tilting pad bearings factory...

Gearbox tilting pad bearings play a crucial role in various mechanical systems, particularly in machinery like turbines, compressors, and other industrial equipment. Their ability to support and stabilize the rotating shafts in these systems ensures smooth operation and longevity. However, like all mechanical components, tilting pad bearings are subject to wear and performance issues that can equipment malfunction if not properly addressed.

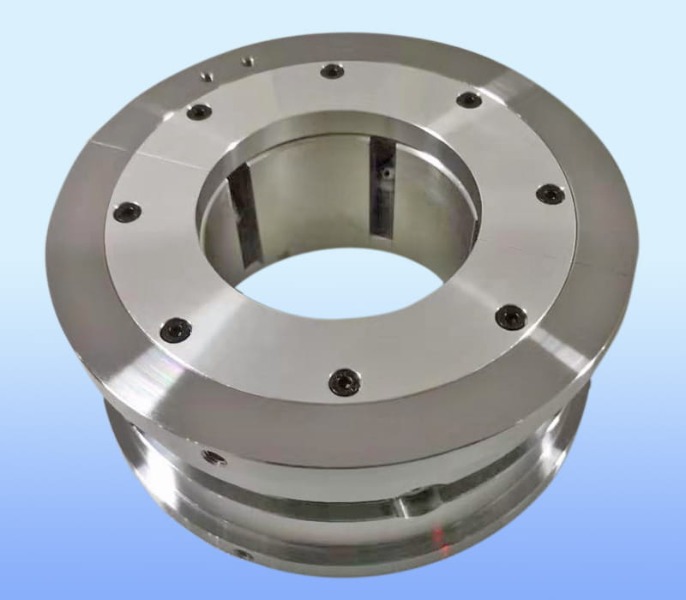

Gearbox tilting pad bearings are designed to support rotating shafts in machinery by providing a stable, low-friction surface. These bearings consist of a series of individual pads mounted on a bearing surface. Each pad can tilt slightly in response to forces and loads, which helps to distribute the load evenly across the bearing surface. This design allows for minimal wear and efficient operation, making tilting pad bearings ideal for applications in heavy-duty machines such as turbines, compressors, and electric motors.

While gearbox tilting pad bearings are generally reliable, they are not immune to issues. Over time, even the best-designed bearings may experience wear or other forms of damage, which can result in performance degradation and equipment failure.

Wear and tear is perhaps the common issue faced by gearbox tilting pad bearings. Continuous motion and load-bearing forces can cause the pads to gradually wear down, affecting the bearing’s ability to function properly. This type of wear can increased friction, reduced efficiency, and eventually premature failure.

Causes:

Prevention:

Lubrication plays a critical role in reducing friction and preventing premature wear of gearbox tilting pad bearings. However, contamination of the lubricant by dirt, dust, or debris can bearing failure. Contaminants can cause abrasive wear on the pads and the shaft, increasing friction and accelerating wear.

Causes:

Prevention:

Misalignment of the gearbox or the shaft supported by the tilting pad bearings can cause uneven distribution of loads. This misalignment can excessive wear on certain areas of the bearing, reducing its lifespan and performance. In severe cases, misalignment can cause catastrophic failure of the bearing or even the shaft.

Causes:

Prevention:

Overheating is another common issue with gearbox tilting pad bearings. High operating temperatures can cause the lubricant to break down and result in thermal expansion of the bearing materials, increasing friction and causing further wear. Overheating can also affect the integrity of the bearing itself, making it more susceptible to failure.

Causes:

Prevention:

Excessive load on the gearbox tilting pad bearings can cause the pads to deform or suffer from accelerated wear. Bearings are designed to handle specific loads, and exceeding those limits can permanent damage. Overloading can also cause increased friction, heat generation, and ultimately, bearing failure.

Causes:

Prevention:

The effective way to prevent issues with gearbox tilting pad bearings is through regular maintenance. Routine checks and servicing can identify potential issues before they escalate into significant problems. Regular cleaning, lubrication, and inspection of components can extend the lifespan of bearings and improve their performance.

Vibration monitoring is an essential part of ensuring that gearbox tilting pad bearings remain in good working condition. Vibration analysis helps detect early signs of imbalance, misalignment, or wear. Similarly, temperature monitoring can provide early warnings of overheating issues.

Proper lubrication is vital for gearbox tilting pad bearings to function efficiently. Using the correct lubricant, maintaining proper lubricant levels, and ensuring regular changes can significantly reduce the risk of contamination and wear.

Ensuring proper alignment during both installation and maintenance is key to preventing many of the issues associated with gearbox tilting pad bearings. Using alignment tools and verifying shaft positioning can help maintain bearing performance.

Proper load management is critical in preventing bearing failure. It is essential to monitor load levels and adjust operations to avoid overloading the gearbox or bearings. Employing overload protection devices can also help manage unexpected surges in load.

Gearbox tilting pad bearings are essential components in many industrial applications, but like any mechanical part, they are prone to issues that can affect their performance. By understanding the common problems—such as wear and tear, lubrication contamination, misalignment, overheating, and excessive load—operators can take proactive steps to prevent these issues. Regular maintenance, proper lubrication, alignment, and load management are essential practices to keep tilting pad bearings in working condition.

Q1: What is the typical lifespan of a gearbox tilting pad bearing?

The lifespan of a gearbox tilting pad bearing depends on the operating conditions, maintenance practices, and quality of the bearing. With proper care, they can last for many years.

Q2: How can I tell if my gearbox tilting pad bearing is failing?

Common signs of bearing failure include increased vibrations, unusual noises, overheating, and changes in operational performance. Monitoring vibration and temperature can help detect early issues.

Q3: Can gearbox tilting pad bearings be repaired, or do they need to be replaced?

In many cases, gearbox tilting pad bearings can be repaired, especially if the issue is caught early. However, if the damage is extensive, replacement may be necessary.

Q4: What are the practices for maintaining gearbox tilting pad bearings?

Best practices include regular lubrication, monitoring for contaminants, ensuring proper alignment, and conducting routine inspections for wear or damage.

Q5: Can overheating of the gearbox tilting pad bearings be prevented?

Yes, overheating can be prevented by ensuring proper cooling, regular lubrication, and using the bearing within its specified operating conditions.