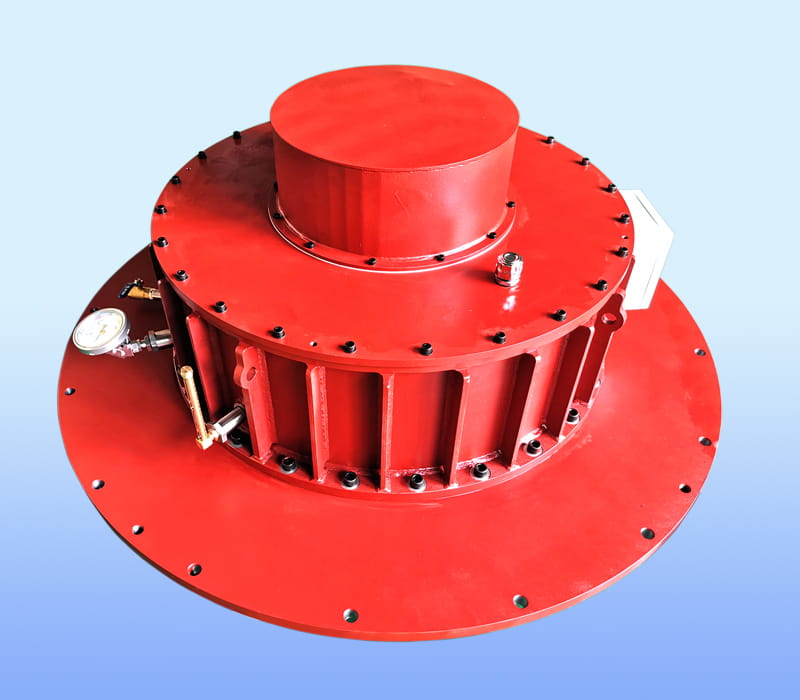

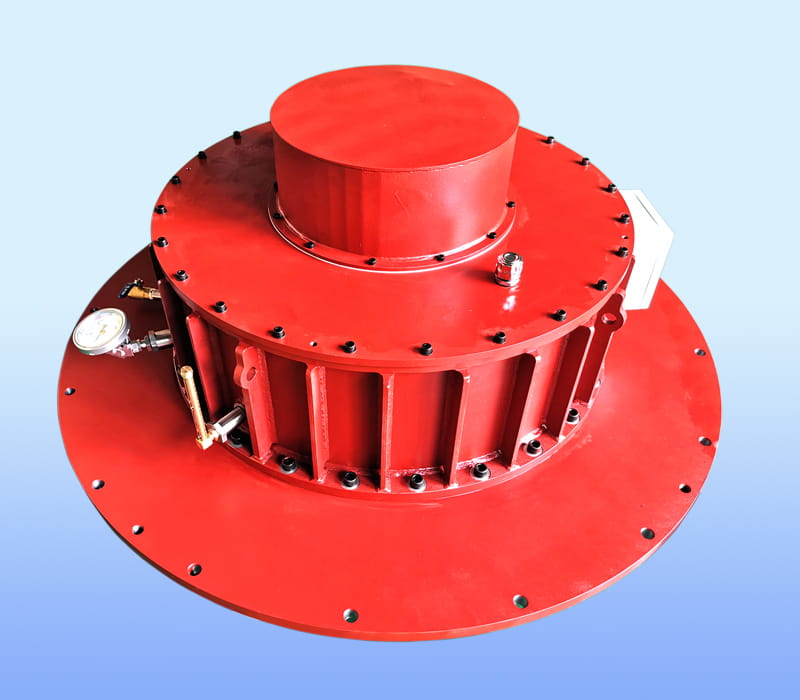

Vertical motor thrust pad bearings are critical components of large vertical motors that provide power to various industrial applications. These bearings are designed to support the axial loads and provide stability to the motor's rotor. In this article, we will discuss the characteristics, design considerations, and maintenance of vertical motor thrust pad bearings.

Characteristics of Vertical Motor Thrust Pad Bearings:

Vertical motor thrust pad bearings are hydrodynamic bearings that operate by creating a thin film of oil between the bearing surface and the shaft. This oil film separates the bearing from the shaft and reduces friction, allowing the motor to operate smoothly and efficiently. The key characteristics of vertical motor thrust pad bearings are as follows:

Load Capacity: Vertical motor thrust pad bearings are designed to support high axial loads, which makes them suitable for large vertical motors.

Low Friction: The thin film of oil between the bearing surface and the shaft reduces friction and wear, which increases the bearing's lifespan.

Self-Lubricating: Vertical motor thrust pad bearings are self-lubricating, which reduces maintenance requirements and operating costs.

Design Considerations for Vertical Motor Thrust Pad Bearings:

Vertical motor thrust pad bearings must be designed to meet specific requirements, including load capacity, lubrication, and cooling. The following are some of the design considerations for vertical motor thrust pad bearings:

Bearing Materials: The bearing materials should be selected based on the application's specific requirements, including load capacity, temperature, and corrosive environments. Common materials used for thrust pad bearings include bronze, brass, steel, and babbitt.

Lubrication System: The lubrication system should be designed to deliver an adequate supply of oil to the bearing surface. The system should also include filtration and cooling to maintain the oil's quality and prevent overheating.

Cooling System: The cooling system should be designed to maintain the bearing temperature within the acceptable range. The cooling system can be either air-cooled or water-cooled, depending on the application's requirements.