ZHEJIANG BHS JOURNAL BEARING CO.,LTD. located in FengXian District of ZheJiang, the company's brand "BHS", is a professional tilting pad thrust bearings manufacturers and Tilting pad bearings factory...

Bearings are divided into many types according to different materials and industries that are not used. It is difficult to tell the difference between good and bad from the appearance. It is necessary to observe carefully. In order to prevent the purchase of low-quality bearing products, we must understand some methods of identification.

Identification method of bearing quality:

1. Introduction of bearing bearing manufacturers First look at the material used for bearing steel. The German FAG bearing is produced by its own professional steel mill, and its hardness and precision are higher than the fake FAG bearing.

2. Using high-input marking equipment, in order to establish the corporate brand image and prevent the product from being counterfeited, a laser marking machine is used, hoping to establish a corporate image and meet international standards, at the same time, use high input to control the product being counterfeited. However, due to the laser The marking machine is controlled by a computer and has the advantages of easy editing such as marking font and size. It can not only effectively prevent counterfeiting, but also increase the difficulty for counterfeiters.

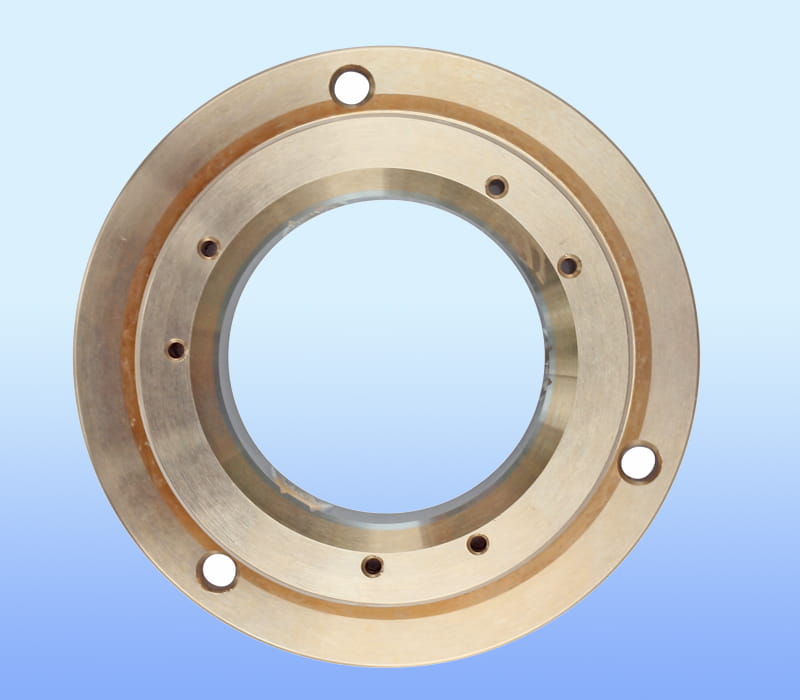

3. Bearing identification method: observation method. Observe the rolling bearing with the naked eye. The inner and outer raceways should be free of peeling marks and severe wear, and be in the shape of an arc groove; all rolling body surfaces should be free of spots, cracks, and peeling; the cage should not be loose, damaged, or worn. , The gap with the rolling elements is not too large.

4. Feel method. The gap between the inner and outer races of normal bearings and rolling elements is 0.005 to 0.010 mm. For the rolling bearing that has been used in one stage, there should be no obvious rattling noise when pinching the inner race with the fingers for axial shaking.