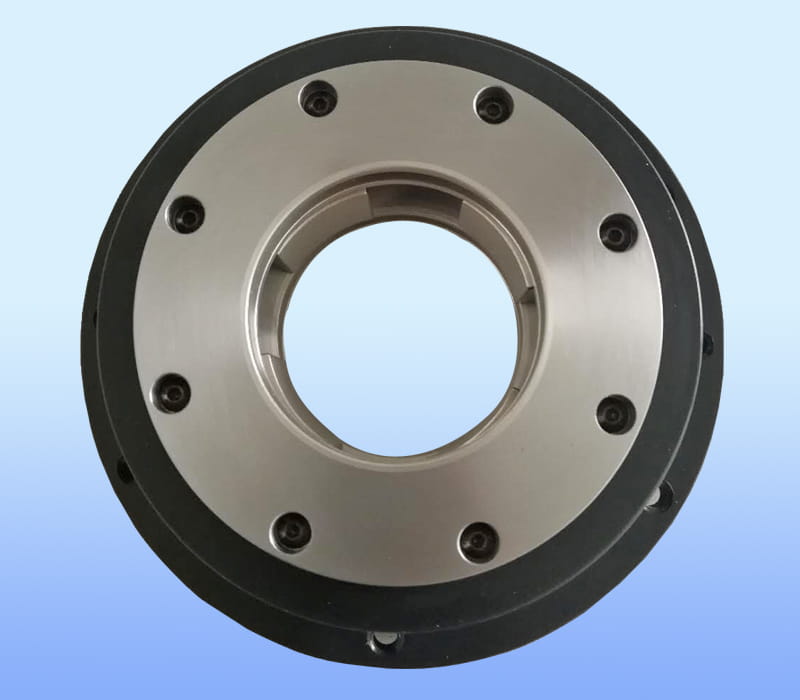

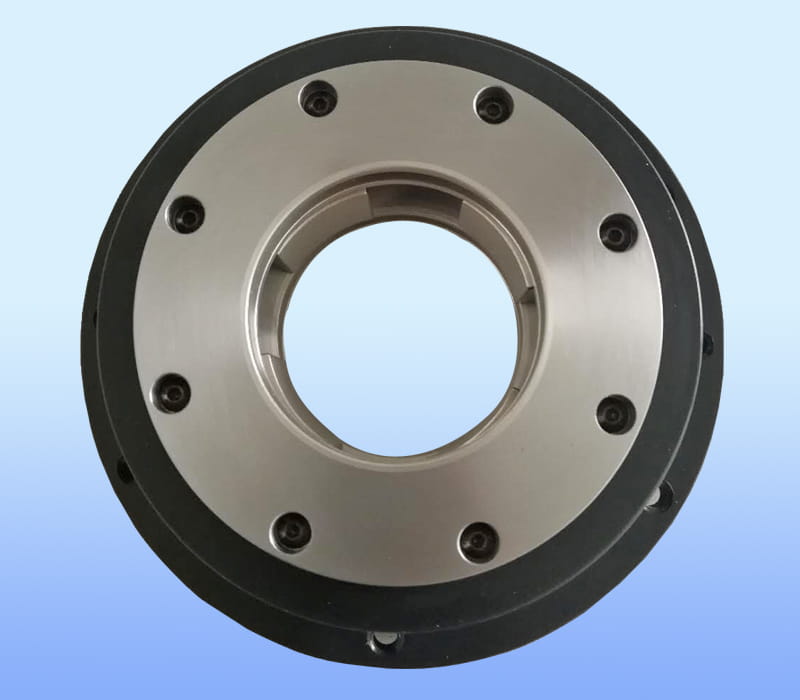

ZHEJIANG BHS JOURNAL BEARING CO.,LTD. located in FengXian District of ZheJiang, the company's brand "BHS", is a professional tilting pad thrust bearings manufacturers and Tilting pad bearings factory...

Many people have serious misunderstandings about bearing service life. General buyers and users believe that the service life of the bearing should be calculated from the bearing processing to the equipment. However, this is not accurate. Simply put, the service life of the bearing should refer to the bearing before pitting. The number of revolutions or hours experienced, what does this sentence specifically mean? In fact, the service life of a bearing is generally defined by the number of revolutions or working hours at a certain speed, that is, the service life of a bearing refers to its actual working time or actual number of revolutions, and within the specified service life No initial fatigue damage should occur to any bearing ring or rolling element.

However, in actual use, the staff of the general bearing distribution found that even the same bearing and the same working environment, the service life would still be different. Why?

There are four main reasons for this situation:

Reason 1: Improper installation

Bearings are precision-machined parts. Any huge external force may cause their deformation. Even if the degree of deformation is very small, it will cause very serious damage. In order to make the installation faster, many installation workers use hammers and other objects to hit the bearings to speed up work efficiency. However, such hits are most likely to cause bearing deformation.

In addition, the installation deviation or not installed in the bearing position, resulting in too small bearing clearance. The inner and outer rings are not at the same center of rotation, resulting in misalignment.

Reason two: pollution

Pollution can also cause premature damage to the bearing. Pollution means that sand, dust, metal chips, etc. enter the bearing.

The main reasons include: opening the bearing package too early before use, causing pollution. The working environment is not clean during installation, causing pollution. The working environment of the bearing is not clean and the working medium is polluted.

Reason three: poor lubrication

Bearings found in market surveys that poor lubrication is one of the main causes of premature bearing damage.

Lubricant or lubricating oil was not filled in time.

Lubricant or lubricating oil is not filled in place.

Improper selection of lubricant or lubricating oil.

Incorrect lubrication method, etc.

Reason 4: Excessive work fatigue

Metal also has its own degree of fatigue, and fatigue damage is a common damage method for bearings.

The common causes of fatigue failure may be:

Bearing long-term overload operation.

Not repaired in time.

Improper maintenance.

Equipment ageing, etc.